Projects

-

- Sand washing machine with hydrocyclone for sale

The cyclone technology is adopted...

-

- How to choose vibrating screen panels ?

The application of vibrating screens...

-

- The Sand Pump Types

The sand pump is a device that increases the energy...

-

- What Is The Reason For The Broken Shaft Of The Motor?

The function of the vibrating motor is to...

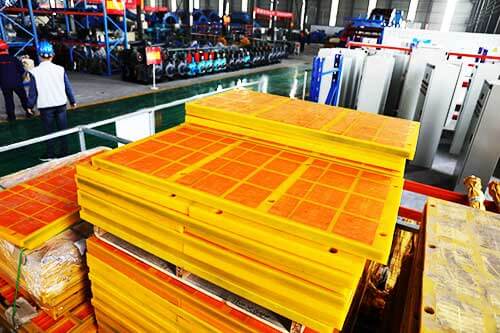

Anti-adhesion Polyurethane Screen Plate

Date: 2021-08-13 From: Longding Author: admin

The anti-adhesion polyurethane screen technology is mainly used in vibrating screens and linear dewatering screens. The screen surface and the supporting ribs hit each other to prevent the adhesion of wet and sticky materials. The extension part of the screen surface covers the joint of the two screen plates, and the extension part vibrates with the vibrating screen to avoid the adhesion of wet and sticky materials. The separation between the screen surface and the screen body improves the vibration and dehydration effect of the screen surface.

The screen surface is provided with sieve holes, and the sieve body is provided with supporting ribs. There is a separation place between the screen surface and the screen body. At least one side of the screen surface is provided with an extension part extending out of the screen body. A clip strip is installed on the support beam. The two sides of the screen body are overlapped on the adjacent beams.

When screening wet and viscous materials, especially in the screening process of steel mills and ironworks, the common problem is that wet and viscous materials will adhere to the sieve plate, which will cause the material on the screen to be compacted, block the sieve holes, and affect the sieving efficiency. Commonly used vibrating screens are mainly divided into two types: fixed screen surface and floating screen surface. At present, there is no good method for a fixed screen surface to completely solve the problem of adhesion and compaction of wet sticky materials on the screen surface. A floating screen surface can solve this problem, but it has the problems of large space occupied by the screen body, low processing capacity per unit area, complex screen body structure, difficult maintenance, and poor screening particle size control.

Leave a Message

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Inquiry