Projects

-

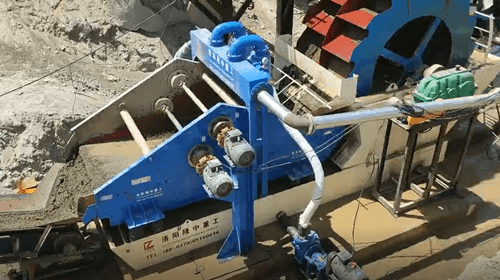

- Sand washing machine with hydrocyclone for sale

The cyclone technology is adopted...

-

- How to choose vibrating screen panels ?

The application of vibrating screens...

-

- The Sand Pump Types

The sand pump is a device that increases the energy...

-

- What Is The Reason For The Broken Shaft Of The Motor?

The function of the vibrating motor is to...

Influencing Factors of Bearing Vibration of Linear Vibrating Screen

Date: 2022-02-25 From: Longding Author: admin

The vibration exciters used in the linear vibrating screen are mostly eccentric shaft exciters and box exciters. The eccentric shaft exciter is easy to install and adjust, but the cost is high, and the eccentric distance cannot be adjusted. The box-type vibration exciter adopts a sector-shaped eccentric block whose relative position can be adjusted, which can realize the adjustment of the excitation force, so as to achieve the purpose of adjustable amplitude.

1. Bearing accuracy

The excitation force of the linear vibrating screen is large, which causes the bearing to bear a large radial force, resulting in strong vibration. The higher the bearing accuracy, the lower the vibration. The waviness of the raceway, especially the rolling element surface, has the greatest influence on the vibration of the bearing. This is due to the high spin frequency of the rolling elements, and the working surface is in contact with the inner and outer raceways at the same time. The magnitude of vibration generated by rolling elements, ferrules, and cages is roughly 4:3:1. Therefore, reducing bearing vibration should first improve the surface machining accuracy of rolling elements.

2. Bearing radial clearance

Too small radial clearance will cause high-frequency vibration, too large will cause low-frequency vibration. This is because a large acceleration occurs at the impact point of the rolling elements and the ring. In the initial stage of impact, high-frequency compression waves are generated irrespective of the mechanical mass and shape of the object, and are transmitted to the inside of the metal. In the later stage of the shock, a mechanical vibration with a lower frequency than the shock compression wave will be generated by the mechanical force. Therefore, a larger radial clearance will increase the vibration of the bearing in the passband.

3. Fitting of the outer ring and bearing hole

The fit between the outer ring and the bearing hole will affect the transmission of vibration. A tighter fit forces the raceway to deform, increasing form errors and resulting in increased vibration. A looser fit can dampen the oil film in the gap. The material properties of the outer ring and the support hole are quite different, especially since the rubber vibration damping ring is placed between them, which can suppress the transmission of vibration.

4. Friction and Lubrication

During the working process of the linear vibrating screen, a large exciting force will cause the elastic vibration of the bearing system. If the lubrication is poor, large friction will be generated, the bearing temperature rise will be too high, the thermal expansion will be too large, and the radial clearance will be significantly reduced, which will intensify the friction and further increase the temperature rise.

Leave a Message

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Inquiry