Projects

-

- Sand washing machine with hydrocyclone for sale

The cyclone technology is adopted...

-

- How to choose vibrating screen panels ?

The application of vibrating screens...

-

- The Sand Pump Types

The sand pump is a device that increases the energy...

-

- What Is The Reason For The Broken Shaft Of The Motor?

The function of the vibrating motor is to...

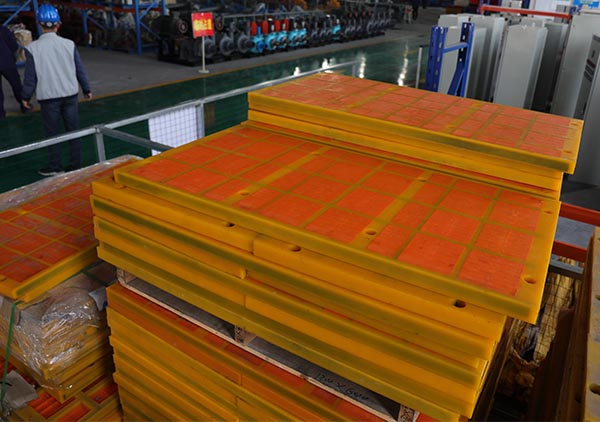

The Production Process Of Polyurethane Screen Plate

Date: 2024-01-12 From: Longding Author: admin

The mesh molding of polyurethane screen plates is an important part of the screen plate manufacturing process. The screen plate will be affected by many factors during the manufacturing process. The first thing to pay attention to is the impact of the properties of the material on the screening.

The Production Process Of Polyurethane Screen Plate

1. In the production process of sieve plates, the size of the sieve holes must first be determined. It is necessary to select the appropriate hole size to make the sieve plate according to the particle size of the material to be screened.

2. Secondly, the factor that affects the shape of the sieve plate is the adjustment method of the mold used when making the sieve plate. The relative position of the screen plate polishing tool and the relative position of the mold above and below the guide rail curve are determined by the guide rail device, generally the relative position on the press. Adjust the press connecting rod length accordingly.

3. In order to prevent the screen holes from being blocked during use, pay attention to the opening direction during processing, with small holes upward and large holes downward. If clogging occurs, the process will need to be modified. and adding an infeed elevator to allow finer-grained materials to go directly into the mill.

4. Increase the pattern on the surface of the screen plate. If there are slight scratches or small dents, they will not be obvious.

5. Reduces shrinkage of screen metal roofing materials. With large decking, metal roofing materials will shrink because even when stretched, the flat surface is difficult to straighten completely.

Leave a Message

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Inquiry