Projects

-

- Sand washing machine with hydrocyclone for sale

The cyclone technology is adopted...

-

- How to choose vibrating screen panels ?

The application of vibrating screens...

-

- The Sand Pump Types

The sand pump is a device that increases the energy...

-

- What Is The Reason For The Broken Shaft Of The Motor?

The function of the vibrating motor is to...

Relate Products

-

- Dewatering Screen

Dewatering screen is widely applied for dewatering, desliming, deintercalation...

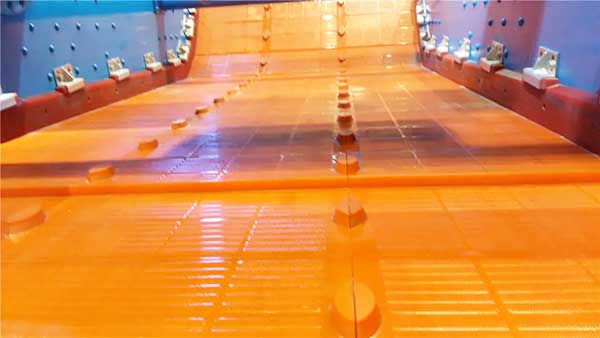

Polyurethane Screen Panel

LDHB polyurethane screen panel is a kind of reticulated product produced with polyurethane as raw material, as long as it is used in mine mineral processing, classification, dehydration and other screening machines to replace metal sieve plate (net).

Polyurethane Screen Panel Introduction

LDHB polyurethane screen panel is a kind of reticulated product produced with polyurethane as raw material, as long as it is used in mine mineral processing, classification, dehydration and other screening machines to replace metal sieve plate (net).

Polyurethane screen panel is mainly used in coal mine, iron ore, copper ore, gold ore and other ore classification, screening, dehydration and other places, is one of the necessary accessories of vibrating screen.

According to the screen holes, LDHB polyurethane screen panels are divided into slit, rectangular, circular and square screen panels.

The friction coefficient between polyurethane and material is low, and because the service life of polyurethane screen panel is 3-5 times longer than that of stainless steel sieve plate, and the number of maintenance and replacement is less, it is the preferred choice in many industries.

LDHB polyurethane screen panel is wear-resistant, moisture-resistant, can work under the condition of water medium, has a long service life, and can avoid the adhesion of wet particles, which is more than 5 times that of ordinary rubber screen panel.

LDHB Polyurethane Screen Panel Features

1. Ldhb polyurethane screen panel has good wear resistance, is not easy to be damaged and reduces maintenance costs.It has good moisture resistance. Under the conditions of water, oil and other media, it reduces the friction coefficient between polyurethane and materials and is more conducive to screening.

2. Reasonable screen hole design and screen plate manufacturing technology make it difficult for material particles to block the screen hole.

3. Good damping performance, strong silencing ability, can reduce noise, and materials are not easy to be broken in the process of vibration.

4. Polyurethane sieve plate has self-cleaning function and high screening efficiency.

5. Corrosion resistant, non flammable, non-toxic, tasteless and environment-friendly.

Leave a Message

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Inquiry