Hot Product

- Hydrocyclone Group

Hydrocyclone group is widely used in coal preparation plant...

- Slurry Pump

Slurry pump is mainly used in mining, power plant, dredging, metallurgy...

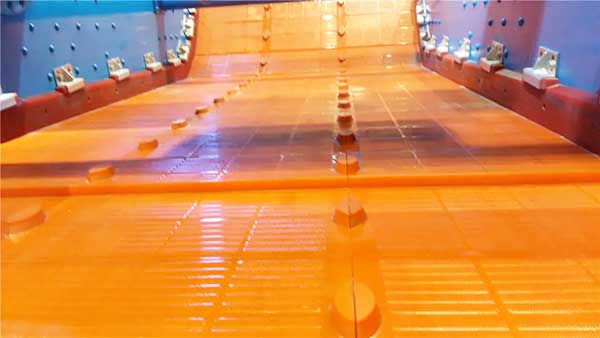

- Polyurethane Dewatering Screen Panel

In addition to the performance of...

Application of Fine Wear Resistant Polyurethane Screen in Iron Ore

Date: 2022-08-12 From: Longding Author: admin

The particle size composition is a decisive factor for the quality of concentrates, so the classification of fine-grained materials is a very important process in the beneficiation process of ferrous metallurgical mines. In the wet classification of fine-grained materials, steel mesh and polyurethane screens are mainly used. LZZG has studied the material and performance of the screen mesh, and has passed the practical application in a concentrator. The results show that the use of a fine wear-resistant polyurethane screen can accurately classify the fine-grained materials, strictly control the upper limit of the particle size of the materials under the screen, and maintain the stability of the final concentrate grade.

1. The performance characteristics of different screen meshes

Stainless steel mesh or nylon mesh is mostly used in fine particle classification in concentrators. The stainless steel screen has a high opening rate, but its rigid mesh structure makes the mesh easily blocked. When the critical particles (1~1.2d) enter the mesh, they will get tighter and tighter under the action of the exciting force, and will not be easy to loosen, so the effective screening area decreases rapidly. In addition, stainless steel woven mesh has a relatively short service life.

The LZZG wear-resistant polyurethane screen has a high opening rate, which can reach 35% according to the aperture of 0.15mm. The screen has a strong self-cleaning ability, does not block holes, and does not paste holes.

2. Application effect of fine wear-resistant polyurethane screen

The iron grade of the raw ore in this mine is 33%~38%, and the beneficiation process is a stage grinding and beneficiation process. The fine screen is used to control the particle size of the concentrate magnetic separation. There are 2 grinding and beneficiation series in the concentrator. No. 1 adopts nylon screen vibrating fine screen as 2-stage grinding and classification equipment, and No. 2 adopts fine wear-resistant polyurethane screen vibrating fine screen as 2-stage grinding and classification equipment. According to the needs of on-site production, the apertures of the two types of vibrating screens are both 0.15mm. The following conclusions can be drawn by comparing the data.

A. The quality and quantity efficiency of the polyurethane screen is 17.65% and 9.03% higher than that of the nylon screen. With the same ore particle size, the average content of the particle size under the polyurethane screen -0.074mm is 8.23 percentage points higher than that of the nylon fine screen.

B. The average concentrate grade using polyurethane screen mesh can reach 65.62%, while the average concentrate grade using nylon mesh is 64.48%. The use of polyurethane screens saves daily maintenance costs compared to nylon screens.

C. High compressive strength, environmental stress cracking resistance, rapid cracking resistance.

D. Great low-temperature resistance. It is still ductile at liquid helium temperature (-269°C), and its main characteristics such as wear resistance and pressure resistance remain unchanged. At the same time, it has wide temperature adaptability and can work at a temperature of -269~80℃ for a long time.

Leave a Message

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Inquiry