Hot Product

- Hydrocyclone Group

Hydrocyclone group is widely used in coal preparation plant...

- Slurry Pump

Slurry pump is mainly used in mining, power plant, dredging, metallurgy...

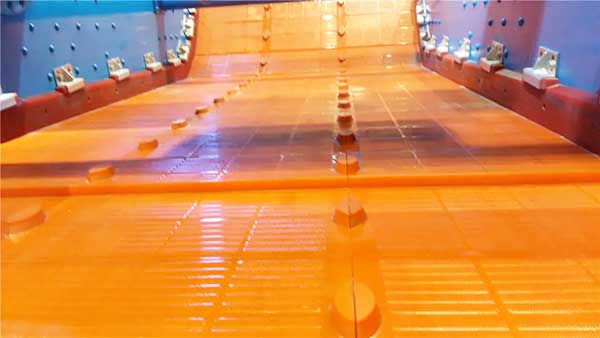

- Polyurethane Dewatering Screen Panel

In addition to the performance of...

How to quickly replace the screen panel?

Date: 2022-07-23 From: Longding Author: admin

The screen panel is very important for the screening effect and output of materials. The screen mesh is a vulnerable part, and daily maintenance and maintenance should be paid attention to. The damaged screen should be replaced in time to avoid affecting the screening effect. The following lists the steps of how to quickly replace the screen panel?

How to quickly replace the polyurethane screen panel?

1. When cutting the dewatering screen, the width of the screen should be the same as the width of the screen frame, and the length should be 50-70mm longer than that of the dewatering screen frame.

2. Tension the polyurethane screen when installing it. The tension of the screen is an important factor affecting the screening power of the dewatering screen.

3. After the dewatering screen is installed in the screen box, the extra 50-70mm screen should be stretched into the corresponding outlet to prevent mixing.

4. The screening difficulty and mesh number of the material should be considered when installing the net-clearing pinball, and it cannot be blindly installed.

5. When the specific gravity of the material is large or the mesh of the device required for the dewatering screen is high, a supporting mesh with a suitable mesh should be added under the screen. Its purpose is to play a supporting effect, reduce the pressure of the material on the screen, and extend its service life.

6. When installing the dewatering screen pressing plate, pay attention to its flatness, and line it with a flexible sponge sealing tape to lock it evenly. This is not only the key to eliminating the occurrence of mixed grades, but also an important factor affecting the service life of the vibrating screen.

How to replace the vibrating screen mesh?

1. Loosen the tie ring screws first, then remove the upper frame, and take off the broken fine mesh. When finished, put on the new screen.

2. Lay the fine mesh flat on the main mesh of the shaker, and put the upper frame back in place. Pull the four sides of the fine mesh tight. Use a pair of universal pliers at the edges of the upper frame and the lower frame at the opposite ends of the fuselage, and then clamp the upper frame and the lower frame.

3. Cut off the screen protruding from the four sides of the shaker. Don’t cut them all, reserve two centimeters.

4. Put the ring back on, loosen the universal pliers, and fasten the ring screw.

5. Use a soft hammer to strike evenly around the ring, then lock the copper nut, and replace the fine mesh. If the main mesh frame and the moving plate are removed during the process of changing the screen of the vibrating screen, it is necessary to pay attention to the fact that the moving orifice plate needs to be firmly embedded in the flange on the bottom surface of the mesh frame when reinstalling.

Leave a Message

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Inquiry