Hot Product

- Hydrocyclone Group

Hydrocyclone group is widely used in coal preparation plant...

- Slurry Pump

Slurry pump is mainly used in mining, power plant, dredging, metallurgy...

- Polyurethane Dewatering Screen Panel

In addition to the performance of...

Hydrocyclone Filter Working Principle

Date: 2021-06-28 From: Longding Author: admin

The hydrocyclone filter working principle mainly includes classification, concentration, desliming, solid-liquid separation, etc. The hydrocyclones are often used in sand washing and beneficiation, as well as tailings treatment. Following is the hydrocyclone structure and hydrocyclone filter working principle.

Hydrocyclone filter working principle

The hydrocyclone can complete various solid-liquid separation operations such as clarification, dehydration, thickening, liquid purification, sand removal, and solid recovery. The separated solid particles can be as fine as 5μm³. At present, many concentrators and sand washing plants have used solid-liquid separation cyclones to replace large gravity thickeners and centrifugal separators to complete the solid-liquid separation.

The solid-liquid two-phase substance enters the shell along the tangential direction through the feed pipe under pressure and makes a rotary motion in the shell. Coarse particles or particles with high density in the slurry enter the periphery of the revolving flow due to greater centrifugal force and are finally discharged from the grit nozzle at the bottom to become grit. The centrifugal force of the fine particles is small, they are in the center of the revolving flow and move upward with the liquid flow, and finally discharged by the overflow pipe to become an overflow.

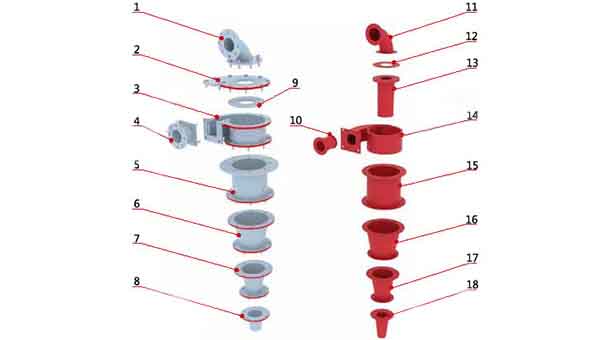

Hydrocyclone filter structure

The cyclone is composed of a feed port, a sand settling port, an overflow port, an overflow pipe, and other structures. Simple structure and large processing capacity. A better solid-liquid separation effect can be achieved by adjusting the depth of the overflow pipe, the angle of the cone angle, the installation inclination angle of the cyclone, and the inlet pressure.

Hydrocyclone specification

The larger the diameter of the cyclone, the larger the production capacity and the coarser the grading particle size.

Large-diameter cyclones should be used that require large production capacity and coarse separation granularity.

Those requiring large production capacity and fine separation granularity should choose a small-diameter hydrocyclone group.

Leave a Message

Here you can submit any questions and we will get back to you as soon as possible. We will not disclose the information you submit to anyone, please rest assured.

Inquiry